“The model the [construction] industry has defaulted to is based around design and build, where responsibility to complete the building design is passed down the supply chain. It has been driven by a desire to protect investment returns and transfer risk. But it has become a barrier to innovation,” says Neil Pennell, head of design innovation and property solutions at Landsec. “It restricts clients from exerting influence once responsibility has been passed to the contractor – which is madness. Would BMW hand over the design of one of their cars to another manufacturer to finish?”

Pennell highlighted the peculiar logic of the construction supply chain while discussing Landsec’s latest project, which is pioneering a new approach that promises to fundamentally transform how construction projects are procured, designed, and constructed. Their “kit of parts” approach creates efficiencies across the construction supply chain through a more standardized and componentized building system named P-DfMA (platform design for manufacture and assembly).

Working with architects firm Bryden Wood, Landsec has developed a prototype at the practice’s Construction Platforms Research Centre in Hampshire, UK. Benchmarked against Landsec’s typical costs per sq m, the project under design is already achieving efficiency gains with a predicted 9.5% reduction in capital cost (against a target of 10%), and a 13% reduction in program time (against a target of 15%). The success of the prototype has earned the system its first real-world application, Landsec’s new office development in Central London.

105 Sumner Street sits directly behind the famous Tate Modern art museum in Southwark. It is a 135,000 sq ft office development comprised of two nine-story buildings. The structural design has been extensively re-engineered from five different floor heights to just two to promote repeatability. Beefy structural columns every 9 meters have been swapped for ‘micro’ columns 3 meters apart to reduce the structural zone. A new procurement approach brings in supply chain stakeholders early to help identify further innovation and efficiency gains. An overall approach that Landsec calls “Office 1.0”.

“1.0 is the construction cost of a ‘perfect’ site, where we can maximize efficiencies in materials, programming, and construction,” explains Pennell in an interview with Construction Magazine. “Where there are, for example, onerous planning requirements or difficult ground conditions, the cost may rise to 1.2 or 1.3 times that baseline cost. It’s a useful ready reckoner when assessing the rate of return on a site.”

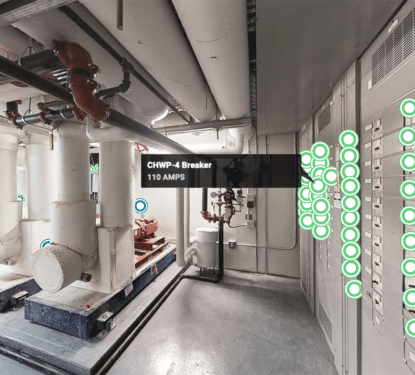

The system has inspired numerous innovative strategies to strive for a “1.0-perfect site” for construction costs. With P-DfMA, building services are integrated within the platform design, enabling more efficient use of space, for example. Deflection on floor slabs, a common problem for pre-manufactured building components, has been reduced by a ribbed concrete slab design supported by the 3-meter column distribution. Thereby facilitating easier installation of facades, which have a regularised design to suit the structural frame. Furthermore, the P-DfMA system improves construction site safety and increases sustainability.

The on-floor MEP (mechanical, electrical and plumbing) kit of parts has been designed to integrate with the superstructure, for example, using fixings pre-cast into the concrete slabs. Thereby minimizing drilling and the dust it produces, creating healthier and safer construction sites. MEP modules are also designed to work with the all-electric central plant, using high-efficiency heat pumps to serve heating and cooling needs within a zero carbon in use strategy. While a forecast 19.4% reduction in embodied carbon per sq meter goes beyond traditional sustainability targets.

“What we have done is taken the kit of parts and applied it to a traditional design, which is a good test for the platform approach, showing that it can satisfy planning requirements, while making a direct comparison with traditional construction methods,” says Jaimie Johnston, global systems director at Bryden Wood.

“And we will take the learning here to other projects – the same structural and MEP components and the same design and procurement principles can be used again,” adds Pennell. “This is our first kit of parts project – by the time we’re on our third or fourth project, we will be achieving higher levels of standardization which should lead to even greater benefits.”

The componentized, kit of parts, Office 1.0, P-DfMA system ticks a lot of boxes for a lot of stakeholders. It offers more control to property developers, it improves safety for construction workers, it’s more sustainable for environmental advocates, and it brings down costs for all. The opposition to standardized building processes has typically been architects and those that care for the diversity of architecture in our urban environments. Pennell and his colleagues are confident that these groups will be satisfied as they strive, with their partners, to change the face of construction.

“This approach retains the architect’s creative freedom. Despite the kit of parts being standardized, these can be put together in countless ways to create a huge range of different spaces and aesthetics, without limiting design ambition,” says Pennell. “Our aim is to become a fundamentally different developer. Digital is the enabler here. It is possible to experiment and prototype much more quickly, so being a follower isn’t an option. You have to innovate and lead to stay ahead of the competition.”

Follow to get the Latest News & Analysis about the Competition in your Inbox!