By now, many have heard of printable electronics. Conductive ink is already being applied in asset tagging and logistics applications through RFID, within circuit boards to replace wiring, acting as radio antennas for vehicles, and even to protect surfaces in cold environments.

As advances continue in printable electronics, the electrical conductivity of the ink is evolving to serve new energy storage functions, opening up a whole new world of possibilities, not least for the built environment.

Researchers from Drexel University and Trinity College in the Republic of Ireland, have collaborated to create an ink from a highly conductive type of two-dimensional material called MXene. Their findings, published in a recent edition of Nature, describe an ink that can be used to print flexible energy storage components, such as supercapacitors, in any size or shape, using an inkjet printer.

“Conductive inks have been around for nearly a decade and they represent a multi-hundred million dollar market that is expected to grow rapidly into the next decade. It’s already being used to make the radio frequency identification tags used in highway toll transponders, circuit boards in portable electronics and it lines car windows as embedded radio antennas and to aid defrosting,” explains Yury Gogotsi of Drexel University. “But for the technology to see broader use, conductive inks need to become more conductive and more easily applied to a range of surfaces,” he continues.

Gogotsi, PhD, is a Distinguished University and Bach professor in Drexel’s College of Engineering, Department of Materials Science and Engineering. The focus of his work has long been the applications of new materials in technology and he suggests that the ink, created in Drexel’s Nanomaterials Institute, is a significant advancement on both material and technological fronts.

“So far only limited success has been achieved with conductive inks in both fine-resolution printing and high charge storage devices,” Gogotsi highlighted. “But our findings show that all-MXene printed micro-supercapacitors, made with an advanced inkjet printer, are an order of magnitude greater than existing energy storage devices made from other conductive inks.”

While researchers are steadily figuring out ways to make inks from new, more conductive materials, like nanoparticle silver, graphene and gallium, the challenge remains incorporating them seamlessly into manufacturing processes. Most of these inks can’t be used in a one-step process, according to Babak Anasori, PhD, a research assistant professor in Drexel’s Department of Materials Science and Engineering and co-author of the MXene ink research.

“For most other nano inks, an additive is required to hold the particles together and allow for high-quality printing. Because of this, after printing, an additional step is required — usually a thermal or chemical treatment — to remove that additive,” Anasori said. “For MXene printing, we only use MXene in water or MXene in an organic solution to make the ink. This means it can dry without any additional steps.”

Created at Drexel in 2011, MXenes are a carbon-based material made up of two-dimensional layers. They have the unique ability to retain their conductive properties when mixed with many liquids, including organic solvents such as water.

These qualities have allowed the researchers to test and produce MXenes in a variety of forms, from conductive clay to a coating for electromagnetic interference shielding to a near-invisible wireless antenna. Now by producing an ink for use in commercially available printers, they hope that they could open up printable electronics and energy storage to every household.

“If we really want to take advantage of any technology at a large scale and have it ready for public use, it has to become very simple and done in one step,” Anasori said. “An inkjet printer can be found in just about every house, so we knew if we could make the proper ink, it would be feasible that anyone could make future electronics and devices.”

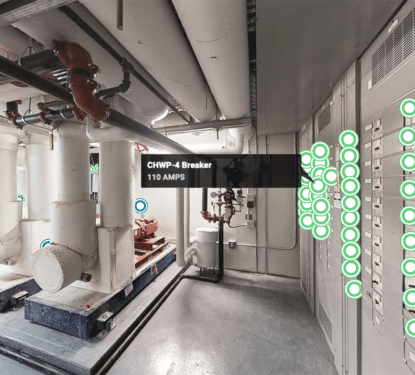

The unique properties and versatility of MXene offers applications in almost every industry and through home printing can have a huge impact on the proliferation of DIY electronics and self-maintenance. In the smart building space, we may consider MXene materials for back-up power in IoT devices, easily replaceable protective layer defending against electrical surges, surfaces that can charge mobile devices, responsive window electronics, and maybe even conductive paints throughout the built environment. This breadth of applications would not only improve our current systems and devices but also inspire entirely new technologies.

“Compared to conventional manufacturing protocols, direct ink printing techniques, such as inkjet printing and extrusion printing, allow digital and additive patterning, customization, reduction in material waste, scalability and rapid production,” Anasori said. “Now that we have produced a MXene ink that can be applied via this technique, we’re looking at a world of new opportunities to use it.”