Like most of the projects Elon Musk is involved in, the plans laid out for the Tesla Gigafactory are on another scale to other net zero buildings and the project has rewritten the rules on how to design, build, and operate a facility. Covering a footprint of approximately 5.4 million square feet, for comparison that is three times the size of Central Park in New York, the innovative gigafactory is a vision of the future.

When completed, the Tesla Gigafactory will be the biggest building in the world and (of course) the biggest net zero building in the world. However, due to the scale, the project has been developed in phases to allow it to operate at the same time, and in its current level of development, it is already a 1.7 million square foot, productive, net zero, smart building.

Elon Musk stated that his concept behind the gigafactory is “the machine that builds the machine” relating to a highly automated facility that builds highly automated vehicles. Viewing the factory as one big machine, in the same way we talk about living buildings, has allowed the development team to rethink energy management and redefine the modern industrial facility. In this research note, we explore this revolutionary building and how it achieves net zero buildings status.

Energy Generation

While the efficiency approaches discussed later are admirable, Tesla has largely achieved its net zero buildings goal through sheer solar power, covering almost the entire space of its vast rooftop. Exposed to the bright sunlight and clear skies of the Nevada desert, Tesla is able to maximize its solar power generation. Costs were undoubtedly brought down with the founding of wholly owned Tesla Solar, a dedicated solar producer, as well as strong partnerships with another Musk venture SolarCity and technology heavyweight Panasonic.

The solar installation that is currently underway will eventually include around 200,000 solar panels that can provide 24MW of electricity and will provide all the building’s energy when paired with Tesla’s batteries. When it’s finished, it will very likely be the largest rooftop solar array in the world, and while it's unclear exactly what the capacity is today, we know it was 3.2MW in Sept 2021 and satellite images show at least a 25% increase by Jan 2022. Tesla confirms it is enough to maintain net zero carbon with current operations.

The gigafactory also aims to develop a large solar array on the planned sun shading for the car park, which alone is over 43 acres, and again with almost unlimited access to stackable energy storage —the complete building will be a power plant in its own right. Some wind power has also been installed and more is very feasible in the local windscape but levels are currently dwarfed by solar generation. A key reason behind the unprecedented scale of electricity generation are the intensive energy demands of the lithium-ion battery manufacturing process.

Energy Efficiency

The entire gigafactory and all its equipment, including energy-intensive manufacturing processes that would normally be powered by natural gas, have been reconfigured to work efficiently on electricity.

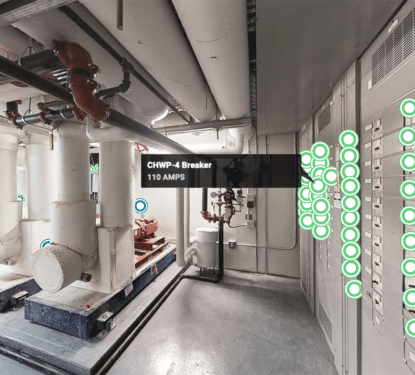

Battery manufacturing, for example, generates high levels of heat that requires energy-intensive cooling processes. Tesla’s solution takes advantage of the desert climate, generating more chilled water than needed during cool nights to use during hot days. The system, which uses one of the largest thermal storage tanks in the world, cuts electricity used in the process by up to 40% and water consumption up to 60%.

“Up front, it seems quite monumental to design, construct, and estimate, but ultimately it eliminates the need for numerous chillers and the amount of energy required to run them,” Rodney Westmoreland, director of construction management for Tesla says.

Likewise, in phases of the production process that require dry air, the building is designed to pull in dry desert air to reduce the use of energy-intensive dehumidifiers. The facility also uses efficient heat pumps to power other processes, such as coating part of the battery cell with a solvent. While waste heat from equipment like compressors or high-temperature ovens can be used both to run the equipment efficiently and to help keep the factory warm in the winter.

“Designing the factory from scratch provided some great opportunities to rethink manufacturing,” says Westmoreland. “We look at challenges from first principles, breaking things down to the very basics of physics and what’s possible, since we’re doing something that has never been done before. As a result, our teams of mechanical, electrical, and manufacturing engineers have spent the last few years creatively building a sustainably powered facility with no onsite combustion of fossil fuels. This was critical to our mission of moving the world to a sustainable energy future.”

Traditional building systems are also designed to the highest specifications. An AI-enabled climate control system has provided energy savings of 10,242.4 MWh or, as Tesla puts it, “the equivalent of driving the average Tesla to the moon and back 63 times.”

The facility is illuminated entirely on LED lights combined with a smart lighting control system to optimize energy consumption alongside human and manufacturing priorities. According to Tesla, the building can save 144 MWh of energy in a month versus traditional lighting setups, “the equivalent of the energy needed to drive a Model S 480,000 miles.”

Leveraging the scale of the project in a competitive process, Tesla was able to inspire and motivate the project’s vendors to find new innovative solutions. In fact, many of the solutions developed for the project have now become industry standards, according to Westmoreland:

“The process pushes the general contractors and design-build firms to change the way that they think, hire, and construct. For example, Tesla engineers partnered with our equipment vendors to look at ways we could reverse-engineer air compressors to handle incredibly hot waste heat, which makes our factory and equipment more efficient. These have now become solutions that vendors can use throughout the industry.”

Embodied Carbon

Tesla has looked for a wide variety of ways to reduce the carbon footprint of its Nevada gigafactory site, and its negative impact on the local environment. In addition to renewable energy generation, the company has undertaken significant in-house projects around waste management and habitat protection, as well as supporting a range of charitable and nonprofit organizations.

A key element for both embodied carbon and the phased approach was prefabrication in the construction process, making the site’s development more efficient and more environmentally friendly. Construction, so far, has generated 83% less waste than a conventional construction project of a comparable size. Excess solar from current operations is also supporting further construction phases.

Over 75% of total waste is diverted from landfills through a variety of recycling methods around the facility. And, after significant R&D investment, Tesla created a new method to utilize new sources of responsibly-sourced lithium battery raw materials. Liquid waste from the new process is then refined and recycled onsite, utilizing solar energy, and saving 30 tanker truck trips per week to an off-site processing center.

A new wastewater treatment plant is also set to come online later this year, 2023, allowing the factory to recycle 90% of process water onsite, and that process water accounts for 90% of total water consumption.

Net Zero Buildings Environment

The Tesla Gigafactory in Nevada is part of the Tahoe Reno Industrial Center (TRIC), the largest industrial park in the world. Aside from Tesla, TRIC includes some of the leading technology companies in the world, notably Google.

A project of this scale is a prized asset for any region and Tesla held negotiations with multiple state governments before settling on Nevada. As part of its incentive agreement with Nevada, Tesla agreed to invest a minimum of $3.5 billion by 2024. Between fiscal years 2015 and 2022, capital investments related to the construction of the Gigafactory totalled $6.2 billion, more than 1.8 times this minimum capital investment requirement. And, since Tesla arrived in Nevada, lithium-ion batteries have become one of the state’s top exported commodities.

It also helps, when building the world’s biggest net zero building, if the owner is one of the richest people in the world but it probably helps more that he is willing to bet big on projects he believes in. A net zero building also makes branding sense for an electric car manufacturer but Tesla could have survived and even impressed people with a 50% clean energy factory. The decision to make net zero buildings of this scale is the kind of visionary leadership we need to see more of across real estate.

“We believe Gigafactory could be a blueprint for a more sustainable construction industry,” Westmoreland says. “When Tesla decided to create a net-zero initiative for the completed facility, we took it seriously. We care as much about the sustainability of our products as we do the way we build them.”