The Bullitt Center in Seattle, WA, is one of the net zero buildings known as a pioneer of “deep green” architectural design. Completed in March 2013, the $32.5 million dollar project was considered an “audacious and provocative experiment and living proof of the economic and technical viability of sustainable buildings” in a 2014 paper by Robert Peña. In this research note, we explore the technological and design approaches that helped the facility achieve a net zero buildings status 10 years ago, and how it has maintained that status over the last decade.

The pioneering building is owned by the Bullitt Foundation, an organization established in 1952 by Dorothy S. Bullitt, a prominent Seattle businesswoman and philanthropist. The primary architect was Core & Shell Miller Hull Partnership, which was supported by developers Point32, MEP firm PAE Consulting Engineers, Luma Design for lighting infrastructure, 2020 Engineering for water systems, and Schuchart as the main contractor.

“There is not a single urban office building in the United States that is truly designed for today’s environment, much less for tomorrow’s, so we set out to build one: the greenest urban office building in the world,” said Denis Hayes, President & CEO of the Bullitt Foundation, in 2013.

Energy Generation

The Bullitt Center generates all its electricity needs on-site through a 242 kW roof-top photovoltaic solar array that consistently produces an energy surplus. To optimize the power production of the photovoltaic array, the team created a new BIM process through which parametric modeling software made it possible to quickly test different geometric solutions to achieve the highest power production.

To ensure net zero buildings status, the facility also relies on 26 individual 400-foot geothermal wells that form a closed-loop heat sink/source utilizing water-to-water heat pumps. The water loops provide comfortable radiant heating and cooling to the office spaces. Ventilation is provided through a dedicated 100% outside air unit with an air-to-air heat exchanger, so that incoming fresh air is preconditioned by outgoing air.

Energy Efficiency

The Bullitt Center’s building envelope greatly exceeded the Seattle Building Code requirements of 2013, using a German designed triple-glazed curtain wall system that was produced locally. The well-insulated walls have been designed to eliminate thermal bridging and dramatically reduce air infiltration. Building massing and orientation, as well as glazing selection, were designed to control heat gain as much as possible on the compact, five-sided urban site, with major glazing areas facing south and north to improve daylighting and solar control.

The building's windows open and close automatically in response to outdoor conditions, while maintaining visibility and daylighting. Electric lighting loads are limited to 0.4 Watts per square foot, less than half the 0.9 W/ ft² required by the Seattle code, and automatic controls dim or turn off all LED lights when sunlight provides adequate illumination.

Geothermally driven heating and cooling is supported by low-velocity ceiling fans, radiant in-floor heating and cooling pipes, shading through exterior automated blinds, and natural ventilation with a passive cooling system. While the ventilation system offers a 65% effective sensible heat recovery and demand controlled fresh air ventilation to further enhance occupant comfort.

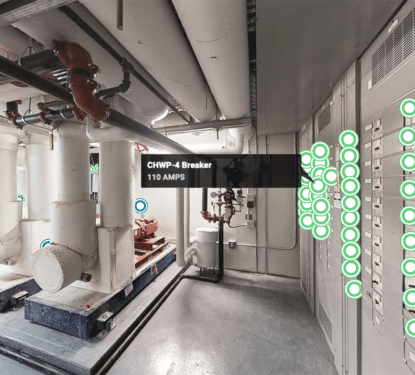

A smart building control system operates the mechanics and logs data about the building, the system monitors, logs and controls the building’s mechanical heating and cooling systems, the supply and wastewater systems, the air supply and exhaust systems, and various pumps. The system also collects and logs data from the weather station as well as indoor sensors, water meters, pump flows, thermal energy, fan usage, and window operations.

The operators took an aggressive approach to reducing plug loads for office equipment, with most equipment limited to a maximum of 0.8W/ft², approximately half the 1.5W/ ft² typical for new office buildings. Furthermore, lease incentives for the tenants are used to ensure energy targets are met and to encourage tenants to employ the most efficient state-of-the-art equipment that meets their professional needs.

Historical building data over the last decade demonstrate that the facility has operated beyond expectations for energy use and regular occupant surveys show that staff are typically satisfied or highly satisfied with workplace comfort. While indoor occupant traffic data have proven the success of design approaches, with significantly higher staircase usage than typical office buildings and a transport mode shift toward public transit when comparing employees before and after moving into the building.

Embodied Carbon

Heavy timber construction is the most visible sign of the Bullitt Center’s embodied carbon credentials, and it was the first major structure in Seattle to use timber since the 1920s. While concrete was initially favored for the building’s superstructure, the locally-sourced heavy timber frame was ultimately selected for all areas where the structure wasn't either exposed to earth or wasn't required to resist potential seismic forces. The resulting hybrid structure is concrete at its base, steel reinforced to resist lateral forces, and timber for gravity loading conditions.

In a city famous for high levels of rainfall, approximately 69% (128,800 gallons) of the facility’s annual rainwater runoff is collected, stored in a 56,000 gallon cistern, treated, and used to much of the potable water needs and 100% of non-potable uses; the remaining 31% is discharged as storm water, ensuring the integrity of downstream hydrology.

Net Zero Buildings Environment

The Bullitt Center was designed and constructed to be certified for the Living Building Challenge by the International Future Living Institute, which assesses projects across seven domains: place, water, energy, health and happiness, materials, equity, and beauty. National initiatives also supported the building’s development. The center's solar array, for example, was funded by US Treasury grants, and is essential to its net zero buildings status.

To encourage positive embodied carbon strategies, the challenge requires that Living Buildings be built on previously developed sites, and this structure was built on the site of a one-story commercial car park, increasing used floorspace from 4000 to 51,000 square feet.

Considering the age of the building, significant credit should be given to the progress stance taken towards the design-build-operate divides that plague smart building development. An integrated design team was created, including owners, contractors, and local community representatives from the earliest stages, which proved essential to achieving net zero buildings energy and water, as well as other major project goals.