Completed in January 2023, The Forge, Bankside, comprises two new-build net-zero commercial office buildings of nine storeys each and almost 140,000 square feet of internal space. It is the first commercial office development constructed and operated in line with the UK Green Building Council’s (UKGBC) net zero carbon buildings framework.

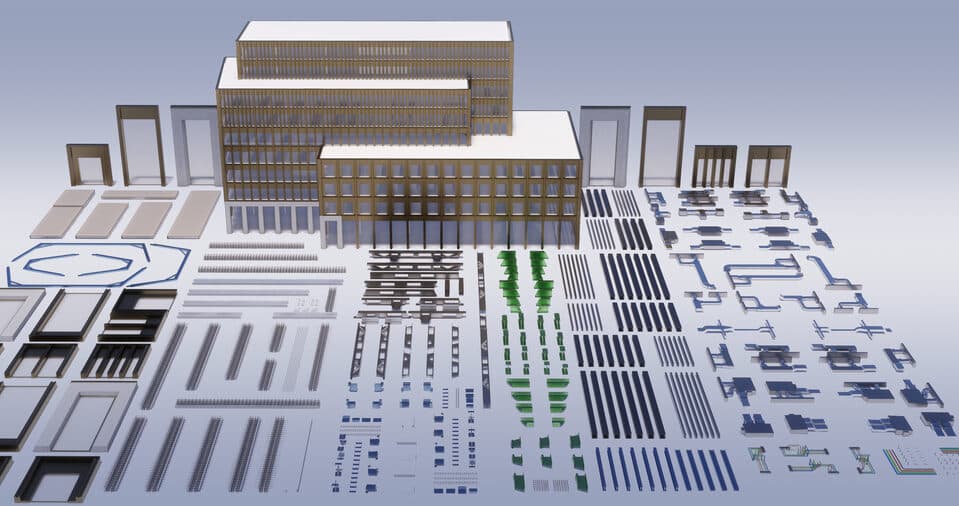

Property developer, Landsec, has constructed and will operate The Forge in line with the UKGBC’s framework definition of net zero buildings. While architects Bryden Wood made this the first office scheme to be built using the highly sustainable “kit-of-parts” platform approach, Design for Manufacture and Assembly (P-DfMA).

“The Forge, at 105 Sumner Street in central London, is a landmark moment for the platforms approach to design for manufacture and assembly (P-DfMA),” says Bryden Wood. “The scale and ambition of the Forge should be a catalyst for change and a major step forward in proving the new business and financial metrics, whole life performance, and supply chain adoption needed – and deliverable – to accelerate the transformation of the construction sector.”

The landmark net zero buildings has achieved the WELL v2 Gold rating, NABERS UK 5 Star rating, and the BREEAM Excellent rating. The developers only decided to update the project from BREEAM 2014 to BREEAM 2018 at Stage 3, meaning some credits were no longer available under the newer version of BREEAM. This made it challenging to bring the project up to BREEAM Outstanding rating.

Energy Generation

The Forge covers 100% of its electricity needs with renewable energy. Over 100 photovoltaic solar panels on the roof of the building provide on-site energy generation, while the remainder is sourced from grid-based renewable energy providers. The building is fully-electric, meaning all systems and devices can utilize on- and off-site clean electricity.

In order to minimize energy use, the architects used passive design techniques before adopting the use of highly efficient electric air source heat pump (ASHP) systems to provide heating and cooling from a 100 per cent renewable electricity tariff.

Energy Efficiency

The Forge implemented a ‘Design for Performance’ (DfP) approach to model the operational energy of the building. The DfP initiative is an industry backed project established to tackle the performance gap and provide an approach, based on measurable performance outcomes, to ensure new office developments deliver on their design intent. This approach has earned The Forge a NABERS UK 5 Star rating.

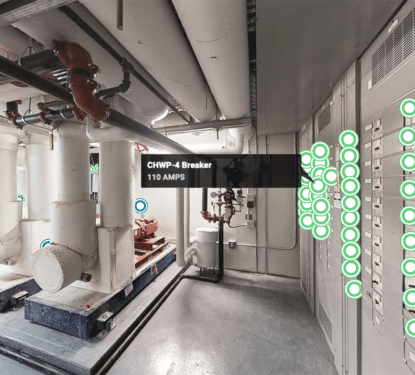

Schneider Electric contributed significantly to promoting the offsite construction process, which included producing package units for the Building Management System controls. The project utilizes the full breadth of Schneider Electric’s EcoStruxure for buildings to enable advanced smart building and energy management solutions.

“The Forge is proof that net zero buildings are possible. Landsec is creating buildings of the future, today. A key element of this is taking intelligent technologies and leveraging the power of smart, clean, and digital electricity – something we call Electricity 4.0 – right from the start,” said Kas Mohammed, VP Digital Energy at Schneider Electric UK & Ireland. “With many companies rapidly running out of time when it comes to net zero targets, I hope the work done by Landsec will provide inspiration and a path forward for many who are uncertain of where to start.”

Embodied Carbon

Overall, the project achieved reduced embodied carbon emissions of 24% through innovative construction methods and material choice.

The off-site manufacturing has reduced the material waste on site, while the procurement of local stone, steel, and concrete further reduced the building’s embodied carbon cost. The structure uses 4% less steel tonnage in the frame and 13% reduction in concrete compared to traditional methods, and the developers used a high recycled content in the steel and façade. The construction required 18% less primary steelwork and 13% less concrete compared to a traditional build.

The sub-structure includes 50% Ground Granulated Blast-furnace Slag (GGBS) within the concrete mix and upper floor self-compacting concrete uses 40% cement replacement for in-situ concrete. Despite GGBS being associated with a longer curing time, this did not impact the construction program as the propping system for Platform-DfMA enabled construction to continue whilst the GGBS was curing.

Looking beyond the lifecycle of the building, the use of standard parts with reversible joints means the building can be dismantled in pieces that can then be reused without the typical carbon waste associated with buildings’ demolition.

Net Zero Buildings Environment

The UK is a one of the leaders in sustainability regulation for buildings and has developed a Net Zero Strategy to transform the construction and real estate industries. In recent years, the UK government has been working to incorporate embodied carbon regulations specifically.

The Forge was selected by Innovate UK, part of the UK governments Research and Innovation body, as a demonstrator project for the Transforming Construction Challenge initiative, in recognition of its design and construction techniques, which have contributed to a circa 25% reduction, to date, in embodied carbon from the initial design stage.

. “Developers, construction firms, architects and occupiers must start working together at scale to deliver buildings like this that minimize whole life carbon and contribute to meaningful progress in the battle against climate change."

Julie Hirigoyen, UKGBC chief executive