Smart buildings are not just about reducing power consumption for cost saving and environmental reasons. Moreover, power management in smart buildings is not just about increasing the energy efficiency of those facilities. Power management is a critical part of many smart building systems but often not considered central to solving the challenges facing the future of smart building development. Two experts from circuit specialist Maxim Integrated have teamed up to demonstrate how better power management could be key to unleashing our intelligent indoor environments.

“The proliferation of intelligent, Internet connected equipment in the smart building requires a proliferation of processors and connectivity interfaces into every controller, sensor, and actuator in the field. This, in turn, places new requirements on system hardware: reduced component size to fit additional electronics in the same chassis, improved energy efficiency to perform within the same or lower thermal budget, and increased electrical/mechanical safety and reliability to reduce downtime,” explain Anthony T. Huynh and Nazzareno Rossetti.

Making things smaller while making them better and safer is the essence of technological development but it is not always easy or straightforward. As one component becomes smaller it may create new issues that can only be solved by developing other components or create opportunities to develop other components to improve the system as a whole. As Huynh and Rossetti highlight, better power management is a critical part of the equation.

“The smaller PCB size that results from miniaturization presents a challenge for thermal dissipation. Thermal-management options, such as heatsinks, are ruled out since board space is at a premium. Fans for forced airflow can’t be used due to sealed enclosures that prevent ingress of dust and pollutants. Therefore, it’s crucial that the power-supply solution is extremely efficient, while delivering higher power and occupying a smaller area than ever before.”

Today, most sensors and actuators utilize a 24V nominal DC voltage bus based on traditional analog relays. This is some way off the anticipated maximum operating voltage for non-critical equipment with industrial applications, which is around 36 to 40 V, and even further from critical industrial equipment, such as controllers, actuators, and safety modules, which must support 60V according to IEC 60664-1 insulation and 61508 SIL standards. Huynh and Rossetti propose that “the obvious choice” for building and industrial control applications is a step-down (buck) voltage regulator, which achieve high efficiency for high-performance systems.

Follow to get the Latest News & Analysis about Smart Buildings in your Inbox!

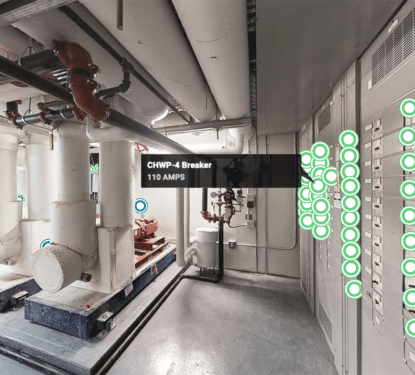

The intelligent built environment is characterized by sensors that convert the real world into a digital format. Sensors are also subject to technological development, and as sensor electronics become more complex they must also maintain size, power and safety standards in order to operate optimally in the current environment. In larger sensor units, voltage regulators offer a power solution with minimal heat generation but safely delivering low voltage power to small advanced sensors becomes challenging.

“The sensor is typically powered by a 24V DC power source. However, a building can be a very challenging environment to install sensors, which require long cable connections to the power source that result in high-voltage transients,” Huynh and Rossetti point out. “Accordingly, the step-down converter inside the sensor must withstand voltage transients of 42 or 60V, which are much higher than the sensor operating voltage. As discussed before, for 24V rails, it’s best to rely on devices that have an operating maximum of 42V.”

Huynh, a Principal Member of the Technical Staff, and Rossetti, an electronic engineer, at California-based Maxim Integrated, also addressed safety and reliability challenges while offering power management solutions. In the case of low-voltage power-conversion systems, they promote isolation. While more complex than non-isolated solutions, the need for small size and high efficiency supports isolation. Isolation also prevents ground loops, when two or more circuits share a common return path, and protects other systems if an incident occurs.

“Protection circuits are the unsung heroes of today’s electronics,” Huynh and Rossetti state. “The long electrical chain, from the AC line to the digital load, no matter the application, is interspersed with fuses and transient voltage suppressors of all sizes and shapes. Protection electronics must handle fault conditions such as overvoltage/undervoltage, overcurrent, and reverse-current flow within the limits of its voltage and current rating.”

Power management is a key element of the smart building and crucial to its development, aside from its important energy cost cutting and environmental roles. Simple power management solutions facilitate advances in technology found throughout smart building systems. Such solutions also allow for smaller devices that can become more pervasive, increasingly the intelligence of the building as a whole. And only with better power management can we ensure the safety and reliability of evolving building systems.

“As the current trend of automation and data exchange in the smart building continues unabated, it will rely on new technologies and approaches to achieve higher comfort, reduce carbon footprint, and improve cost. The adoption of these technologies introduces challenges in terms of energy efficiency, miniaturization, and system reliability,” summarize Huynh and Rossetti before concluding that their proposed “power-management solutions overcome the critical challenges faced by today’s smart buildings.”